OSWAL ENGINEERING CORPO.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to OSWAL ENGINEERING CORPO.

Extruder

Oswal Engineering Corporation supplies the Single Screw Extruders. The Screw and Barrel are most important elements of the Extruder. The Barrel is made of special alloy steel and is honed and nitrided. The Screw is made up of EN material and nitride and hard chrome plated. The machine comes with a hopper dryer and loader. The Screw is combined with the barrel having a properly equilibrated geometry. Extruder control is through Modular Automation system which is assembled in line and allows the customer to synchronize it with the complete line.

Advantage :

- Robust construction and heavy frame.

- Higher output.

- Good melt homogeneity.

- Low power consumption.

- Simple Panels for effective and efficient usage.

- Standard parts for easy replacement.

- Branded drives and motors used for faster service.

- Can be customized.

- Minimum vibration and sound is produced.

- Internationally acclaimed and best quality.

- Simple design for effective troubleshooting and maintenance.

- Helical gear box.

Grinders

Introduction :

Our special thick steel structure absorbs most of the load and noise. The unique vertical feeding system helps eliminate throwbacks and uniform material discharge. Different options of grind size offer 3 – 7 mm plastic grinds.

Separate designed hopper and granulating chamber can be separated easily, while large underbody is equipped with shock-absorber for maintaining stability during work.

OEC grinders offer a wide range of capacities (from 10 kgs/hr to 225 kgs/hr) with different mouth sizes.

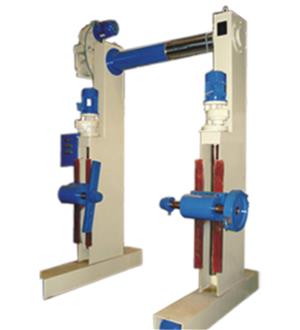

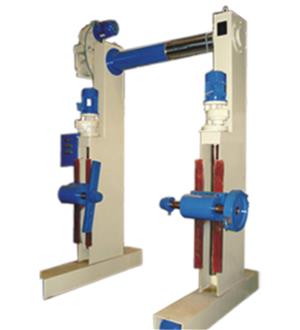

Haul Off Catarpullar

Oswal Engineering Corporation supplies the Haul Off Catterrpullar. The Haul Off Catterpullar has fine accessibility of mechanical, electrical and pneumatic components. Equal amount of pressure is applied on the length of the cables with the help of gripping rollers. Chain system is used to pull the cable with the help of rubber pads. Line speed can be adjusted as required.

Bunching Machine

Oswal Engineering Corporation supplies the High Speed Double Twist Bunching Machine. The machine is capable of bunching of copper wire ranging from 7 to 120 wires of 38 or 36 gauge provided with traverse arrangement for proper winding and with proper cover for safety. The machine is balanced properly so as to give vibration less operation.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.